How We Made It Happen: A Must-See Lift Station Success Story

When a distributor partner faced a pressing challenge, they turned to All Current for a solution. What began as a straightforward request soon evolved into a complex project, that explored our potential to support our customer in every possible way. This is a story of teamwork, creativity, and dedication to helping our customer overcome obstacles and achieve success.

The Initial Request: Meeting Tight Deadlines with Confidence

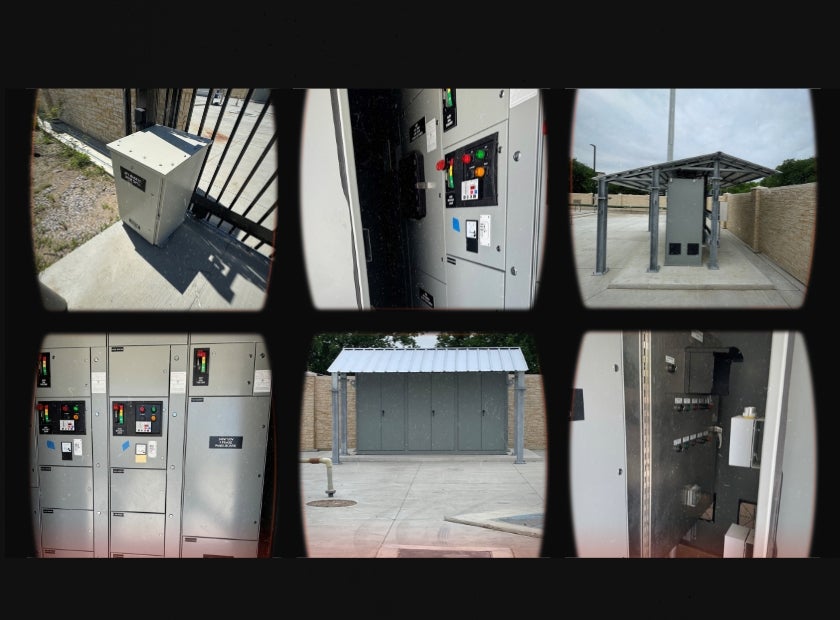

The project began with our distributor partner needing an MCC dropover and a custom-designed canopy to protect a crucial lift station. The timeline was tight, but we were confident in delivering top-quality solutions on schedule. Our team quickly mobilized, drawing on our extensive experience and robust resources to plan and prepare for the project. We were prepared to tackle any issues that might arise to ensure our customer received the best possible outcome.

An Unexpected Setback: Rising to the Challenge

As we prepared to execute the project, we received troubling news: the original MCC shipment from the factory had been delayed. This delay threatened the entire project timeline, potentially causing significant setbacks for our customer. At All Current, we don’t back down from challenges. Instead of waiting idly, All Current took on the build of the MCC ourselves, leveraging our in-house expertise and resources to ensure it was ready within the required timeframe. This decision involved meticulous planning and coordination among various teams. Our engineers and technicians worked tirelessly to ensure the MCC met all specifications and quality standards.

A New Problem Emerges: Tackling Installation Issues

Installation day arrived, and the team was ready to implement the MCC and canopy. However, another significant issue arose: the motor for the gate surrounding the MCC unit was installed outside the gate instead of inside, posing a security risk and another potential delay. Knowing our track record for problem-solving under pressure, the contractor and distributor turned to All Current again. Our talented designers quickly devised a custom stainless steel locking dropover to secure the misinstalled motor, addressing the problem and enhancing the installation's security. This quick turnaround was possible due to our team's agility and commitment to finding innovative solutions.

Meeting the City’s Requirements: Adapting to Last-Minute Changes

Just when we thought the hurdles were behind us, the city engineers overseeing the project made an additional request: they wanted the stainless steel dropover to be painted. This wasn’t part of the original plan, but we understood the importance of adhering to all specifications. We sourced a special paint that met the engineers’ standards and seamlessly integrated this final touch into the project. Our procurement team and designers collaborated closely, ensuring the painted dropover met expectations.

Delivering Against All Odds: A Triumph of Teamwork and Innovation

Despite the series of challenges, All Current successfully delivered a fully functional MCC, a custom-designed canopy, and a locking, painted stainless steel gate motor dropover. All components were completed and delivered on time, reflecting our dedication to excellence and ability to adapt to unforeseen circumstances. Every member played a crucial role, from the engineers who designed the components to the technicians who executed the builds and the project managers who ensured everything stayed on track.

Turning Challenges into Success Stories

This project underscores the power of collaboration, adaptability, and dedication. At All Current, we are honored by the opportunity to contribute to our clients' success stories. Our journey with this project reaffirms our commitment to exceeding expectations and forging lasting partnerships through innovation and unwavering dedication. Count on All Current for your next project; we're ready to help you succeed!